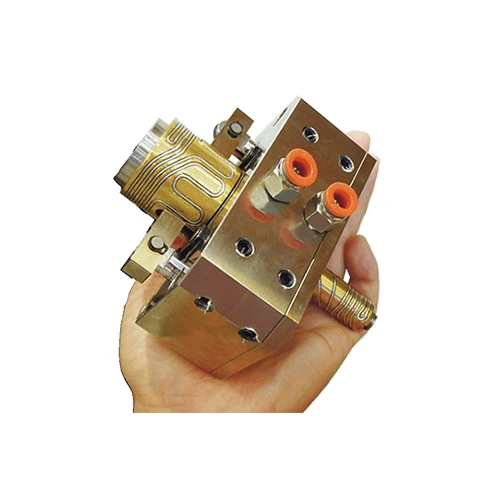

Single Valve Gate Hot Runner System

Categories : Hot Runner Systems

Dual-cylinder, powerful for gate seal. Nice gate mark. All in one, easy to install. Customize for your need.

VALVE GATE-SVDT

Categories : Hot Runner Systems

For the valve pin bushing is integrated with the nozzle, the structure of manifold become very simple, and therefore this series is most suitable for the multi-cavity application. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gat mark.

VALVE GATE-NL SVDP

Categories : Hot Runner Systems

Pneumatically shut-off nozzle can create a flawless gate with no drooling and no stringing. Gate only leaves a small witness ring. The large gate openings are possible. This makes processing at high-flow rates much easier. The valve pin can be closed allowing plastification during mold open stages.

VALVE GATE-AVMT

Categories : Hot Runner Systems

Suitable for large-scale parts or complex shape parts. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle gate. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gate mark. For the multi-gate mold design, using the sequence control can eliminate the weld line problem.